Dureco in co-operates with Westrac (Caterpillar dealer) provides insight into Motor Grader utilization and blade operation.

Initial Stage

Westrac sought information on blade engagement with ground. Simple blade is engaged with the ground or not. Original idea was to use a pressure sensor and monitor hydraulic. Due to use of pressure compensation in hydraulic systems this approach proved to be dead end.

Westrac needed a solution to be able to reliably detect whether the blade was engaged with the ground or not. While the easy solution using a pressure sensor and monitor hydraulic system was tested. It was determined to be an unreliable solution, due to the pressure compensation found in hydraulic systems.

Westrac engaged Dureco to create a custom solution to reliably detect blade engagement that would be easily replicated across their fleet

Right Tools

Selecting the right approach and tools is a key for long term reliability and consistency. After some research into methods that could be used, it was determined that Vibration analytics could be used to detect blade engagement.

We needed a way to run vibration analysis in real-time and collate with other events such as Vehicle Information Management System (VIMS) information and location. All the processing needed to be done in the field on the vehicle to prevent problems with time synchronisation.

DiBOX from Alitec

DiBOX is a real-time vibration analytics device that can process up to 4 signals/sensors simultaneously. One of the features of the DiBOX is that it supports Modbus protocol, where the unit runs analytics on incoming signals and provides the results as Modbus registers. Modbus is a very common protocol and as such this made it much simpler to integrate the analytics information into our solution for real time reporting.

Dureco is Alitec partner and distributor for ANZ region.

IDEGG 4G Router from Dureco

The IDEGG 4G Router is a hardened device, and was designed to withstand vibrations and shock making it perfect for vehicle applications.

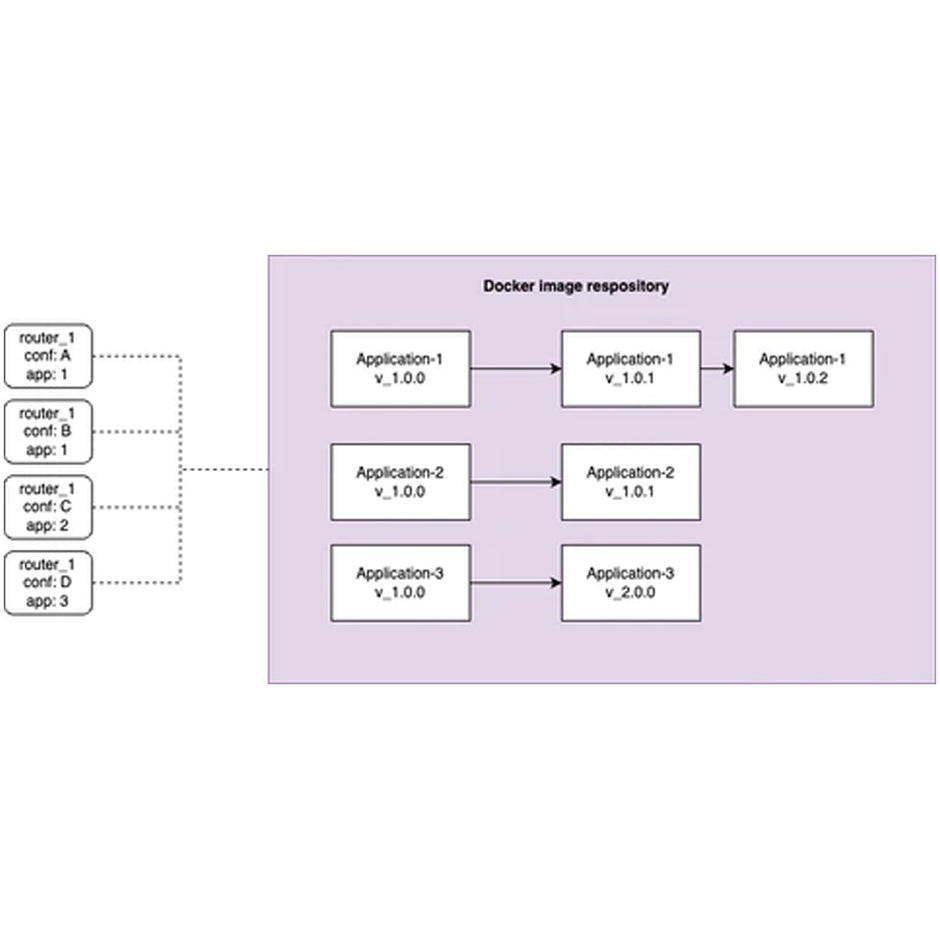

Inside this rugged enclosure is an Advantech 4G router, which can run Advantech pre-made apps, and also supports multiple programming languages including Node.JS, Python and C++. Using the router and ruggedized housing for mounting on vehicles was no brainer.

The final solution was to run Node-Red on the IDEGG device and use this to read the Modbus registers from the DiBOX. This analytics data is then processed on the IDEGG unit (in the field) to provide reliable real-time feedback on the state of the blade engagement. The application guarantees reliable delivery and communication with upstream systems and using a flexible platform guarantees fast deployment and integration with the customer’s own systems..

Available data

The solution does collect and store below data. The store and export formats are customisable, which also applies to the communication with 3rd party API.

- Date, Time

- Location

- Event - Grading, Grading in reverse, Abuse level

- Category

- Last report time

- Engine run

- Blade load factor - with some materials

- Reverse engaged

Optionally vehicle information can be accessed and added to the same timestamp for easier datamining.