Product Info

Features

Thermoplastic elastomer and reactive rubber of recycled tires

Sound impressive, doesn't it? Pneumatique!Pneumatique - Thermoplastic Elastomer

WHY SO SPECIAL?

There something more of unique – and secret – composition of this 3D filament. Maybe it’s all about the miles that’s those tires travelled, before being revived into “fuel” for your creations and becoming even more special or maybe we owe it to explosive mix between swiss precision and italian passion. Actually, what else could you ask for?

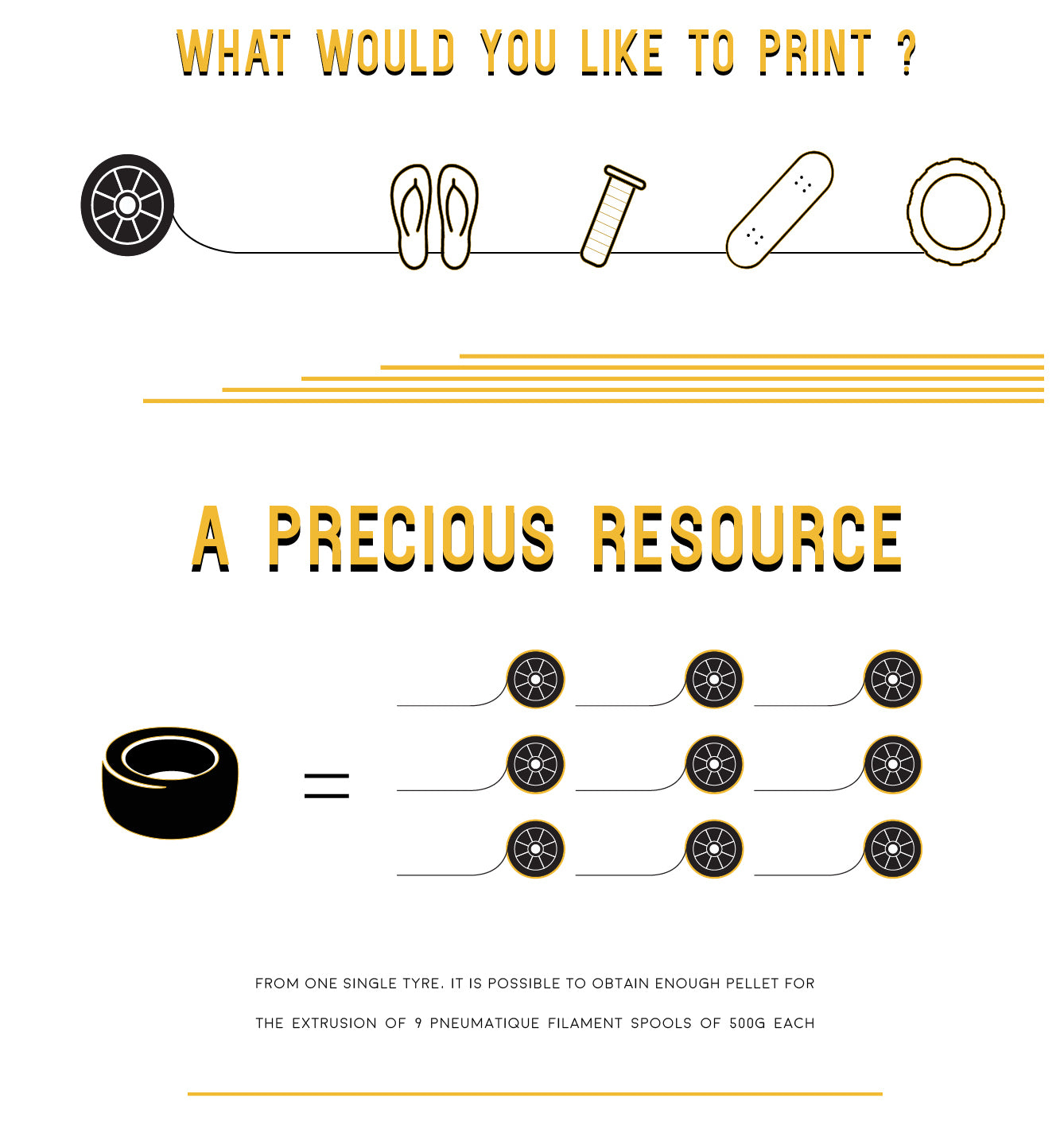

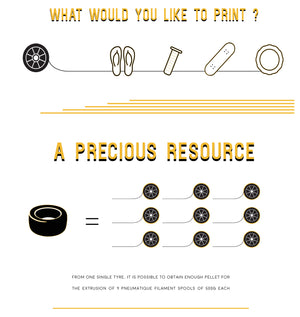

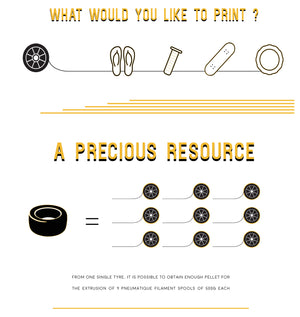

A PRECIOUS RESOURCE

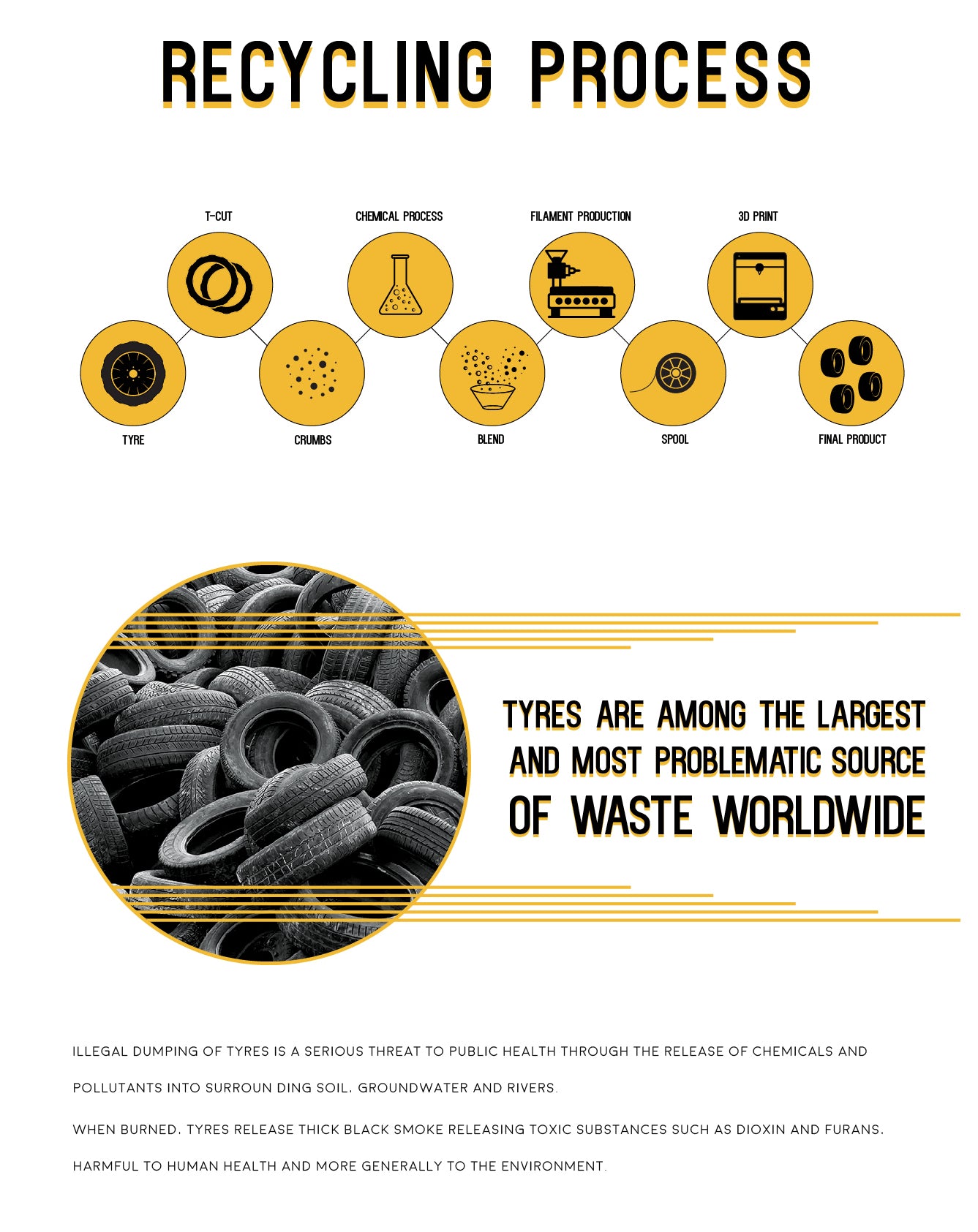

From one single tire it is possible to obtain enough pellet for the extrusion of 9 pneumatique filament spool of 500gr each. Illegal dumping of tires is a serious threat to public health through the release of chemicals and pollutants into surrounding soil, groundwaters and rivers.

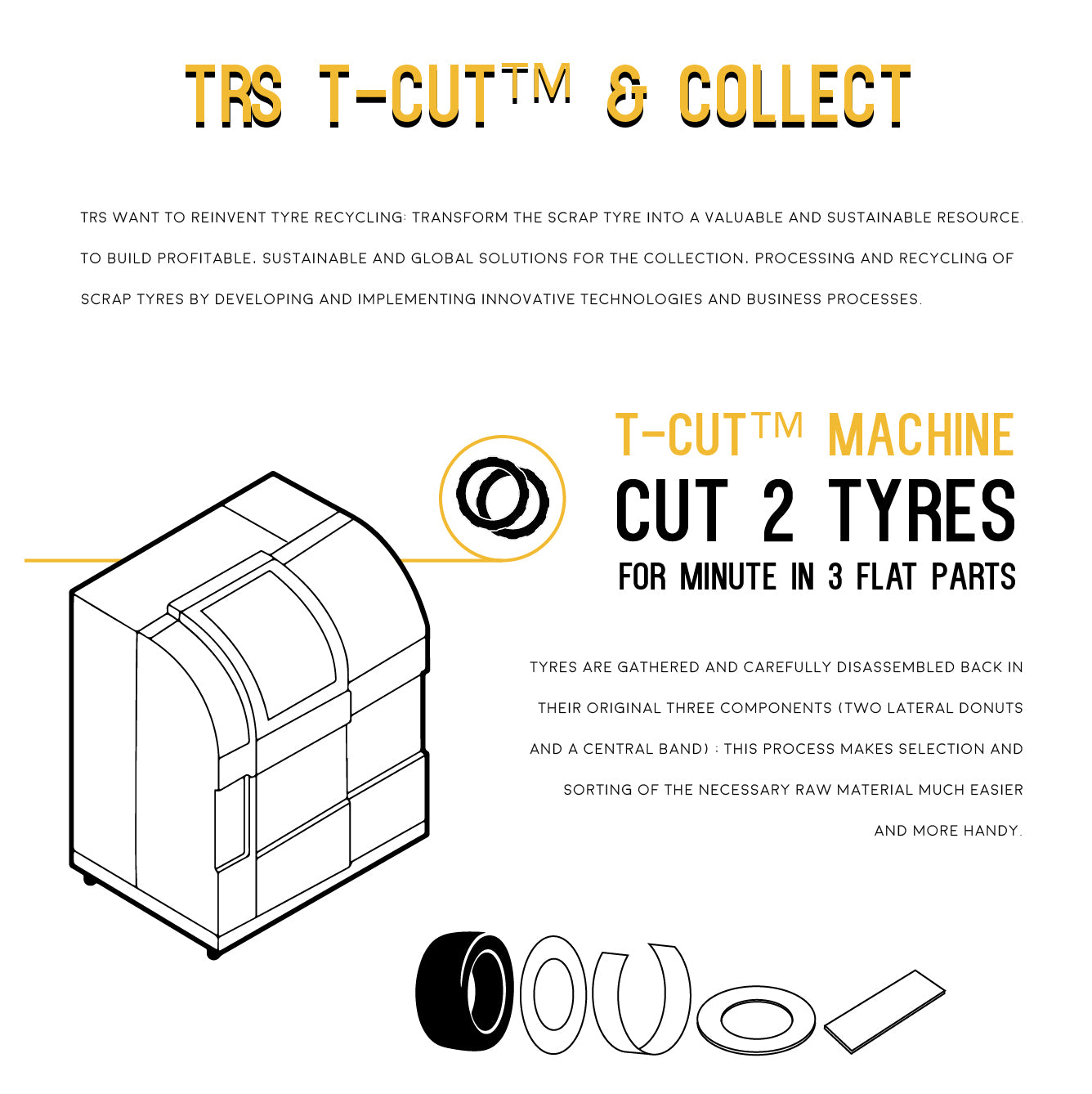

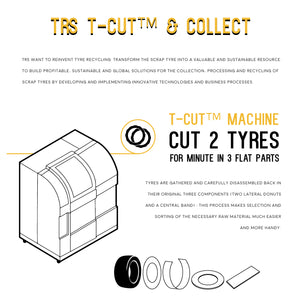

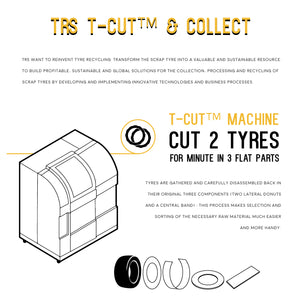

TRS T-CUT and COLLECT

TRS want to reinvent tire recycling transform the scrap tire into a valuable and sustainable resource to build profitable, sustainable and global solutions for the collection, processing and recycling of scrap tires by developing and implementing innovative technologies and business processes. Tires are gathered and carefully disassembled back in their original three components ( two lateral donuts and a central band) : this process makes selection and sorting of the necessary raw material much easier and more handy.

Printing Suggestions

Suggested printing specification

- Extruder temperature - 220 C° +10/-5

- Bed temperature: cold to 45C°

- Build surface material: glass, blue tape, kapton tape, buildtak, PEI

- Print speed: 25-35 mm/s

- Fan: 0-50%

- Minimum nozzle dia: 0.30 mm

Specifications

Material properties

- Diameter: 1.75mm

- Shore Hardness: 93 shA (ISO 62)

- Density: 1.24 g/cm3 (ISO 1183)

- Elongation at break: 600 % (ISO 37)

- Compression set (70°C): 45 % (ISO 815)

- Tensile strain: 55 MPa (ISO 37)

- Abrasion loss: 30 mm3 (ISO 4649)

- Charpy Impact at 23°C: No Break kJ/m2 (ISO 179)

- Charpy Impact at -30°C: No Break kJ/m2 (ISO 179)

Features

Thermoplastic elastomer and reactive rubber of recycled tires

Sound impressive, doesn't it? Pneumatique!Pneumatique - Thermoplastic Elastomer

WHY SO SPECIAL?

There something more of unique – and secret – composition of this 3D filament. Maybe it’s all about the miles that’s those tires travelled, before being revived into “fuel” for your creations and becoming even more special or maybe we owe it to explosive mix between swiss precision and italian passion. Actually, what else could you ask for?

A PRECIOUS RESOURCE

From one single tire it is possible to obtain enough pellet for the extrusion of 9 pneumatique filament spool of 500gr each. Illegal dumping of tires is a serious threat to public health through the release of chemicals and pollutants into surrounding soil, groundwaters and rivers.

TRS T-CUT and COLLECT

TRS want to reinvent tire recycling transform the scrap tire into a valuable and sustainable resource to build profitable, sustainable and global solutions for the collection, processing and recycling of scrap tires by developing and implementing innovative technologies and business processes. Tires are gathered and carefully disassembled back in their original three components ( two lateral donuts and a central band) : this process makes selection and sorting of the necessary raw material much easier and more handy.

Printing Suggestions

Suggested printing specification

- Extruder temperature - 220 C° +10/-5

- Bed temperature: cold to 45C°

- Build surface material: glass, blue tape, kapton tape, buildtak, PEI

- Print speed: 25-35 mm/s

- Fan: 0-50%

- Minimum nozzle dia: 0.30 mm

Specifications

Material properties

- Diameter: 1.75mm

- Shore Hardness: 93 shA (ISO 62)

- Density: 1.24 g/cm3 (ISO 1183)

- Elongation at break: 600 % (ISO 37)

- Compression set (70°C): 45 % (ISO 815)

- Tensile strain: 55 MPa (ISO 37)

- Abrasion loss: 30 mm3 (ISO 4649)

- Charpy Impact at 23°C: No Break kJ/m2 (ISO 179)

- Charpy Impact at -30°C: No Break kJ/m2 (ISO 179)

PNEUMATIQUE – 1,75ø – 500gr Spool

- Regular price

- $85.00

- Sale price

- $85.00

- Regular price

-

Couldn't load pickup availability